THE ALPHALINER

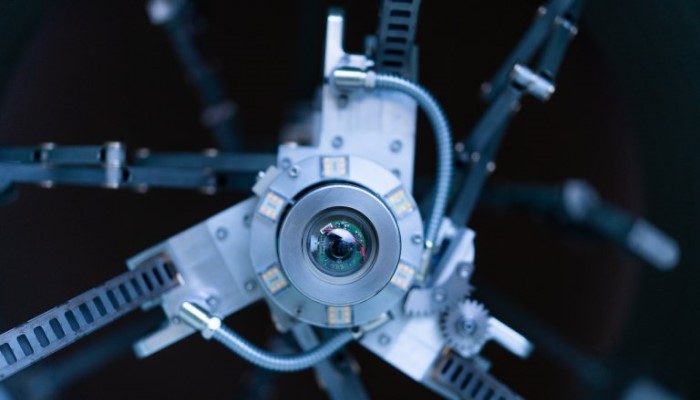

ALPHALINER® is a seamless, glass-reinforced and spirally wound liner that can be tailored to fit your exact specifications. It’s available in diameters ranging from 6 to 72″ (15.24 cm to 182.88 cm) and lengths in excess of 1,200 feet (366 meters). ALPHALINER® can accommodate a variety of pipe shapes, ranging from circular, ovoid, and arch to rectangular and special cross-sections.

Reline America offers you an array of proprietary resin formulations that can be adjusted to meet your project’s site-specific technical requirements for physical and chemical-resistance performance. If you’re unsure of which resin formulation you need, no worries – our in-house technical team can help you select the optimal formulation for your project.

ECONOMICAL AND SAFE: THE ALPHALINER WITH INTEGRATED SLIDING PROTECTION AND INTEGRATED PRE-LINER

RELINE doesn’t just make better products, we have evolved the process required to install them.

All Alphaliners are equipped with integrated sliding protection, or optionally with an integrated pre-liner. This increases safety and speed of construction during installation. Depending on its size and weight, the pipe liner material is exposed to considerable frictional forces during installation. Even small irregularities or sharp-edged obstacles, which may still be present despite careful preparation of the channel with milling robots, are capable of damaging the outer casing, impairing the functionality of the pipe liner.

Alphaliner’s integrated pre-liner also offers additional protection against the resin coming into contact with water, in the event of damage to the outer skin. In addition, Alphaliner is equipped with integrated sliding protection in the lower area, with an additional stable outer skin that is firmly welded to the tubular liner. In the variant with integrated pre-liner, the tubular liner is supplied complete with an additional outer cover.

DEFINED WEAR LAYER ENSURES LONG SERVICE LIFE

Alphaliner has a unique protective wear layer, which is defined in terms of its thickness, on the interior surface of the liner. This complies with the requirements of industry standards DWA-A 143-3 and DIN EN ISO 11296-4. This protective wear layer does not count as part of the composite wall thickness (the part of the composite liner wall that is structurally relevant).

This protective wear layer is at least twice as thick as the abrasion resistance established by the Darmstadt Tipping Trough Trial. It protects Alphaliner against mechanical wear and stress, such as occurs during high-pressure flushing. Alphaliner has a lot of very high safety reserves, ensuring a long service life; typically at least 50 years, and sometimes more.

A SUSTAINABLE SOLUTION FOR EVERY PIPELINE REHABILITATION PROJECT

Innovative design. Wide range of systems. Long-term sustainability Every pipe rejuvenation project requires its own installation approach. Every pipeline material and configuration is different. To allow for these variations in municipal and industrial applications, we offer many Alphaliner formats for your specific needs.

ROI ADVANTAGES

Nothing crushes profit margins like inefficient or failed liner installations. That’s where ALPHALINER® steps in, with a complete system that’s field-confirmed for ease of installation, backed by trained, certified installers. With its superior durability, risk management just got a whole lot easier.

ALPHALINER 500G

ALPHALINER 1800H

ALPHALINER PN

ALPHALINER AQUA.UV®CIPP

ALPHALINER HP

ALPHALINER ECO

ALPHALINER ESD

PLEASE CONTACT US FOR A FREE QUOTATION AND TELL US MORE ABOUT YOUR PROJECT

CAN’T DECIDE WHICH ALPHALINER IS RIGHT FOR YOU?

Reline America, Inc.

Corporate Headquarters

116 Battleground Avenue, Saltville, VA 24370 USA

Toll Free: 866 998 0808 | Local: 276 496 4000

info@relineamerica.com

Copyright ©2024 Reline America Inc.