UV SYSTEM

Our innovative UV technology is developed and produced in our own American factory. The system technology was developed from practice, for practice…reflected in many intelligent innovations.

Contractors know full well that time is money. So do we, which is why we customize our equipment to our liners and each installer. This makes installing our ALPHALINER® ultraviolet-light cured, glass-reinforced pipe (UV GRP) liner a totally user-friendly process – with risk-management and profitability top-of-mind.

With the introduction of our new UV lamps—with a total output of 24,000 W—even hose liners with very large dimensions (up to DN 1800) and high wall thicknesses (up to 20 mm) can be cured quickly and safely using only UV light.

Depending on the system, the power consumption of the lamps in RELINE UV curing systems can be adjusted in stages, from 300 W to 4,000 W. This enables an exact setting of UV light output for the respective GRP hose liner, as well as the fastest curing speeds available.

RELINE UV curing systems have the highest curing performance on the market. They are equipped with permanent performance “smart” monitoring that automatically compensates for the gradual drop in performance of individual lamps over time.

The operation of our unique lamps is constantly checked by electronic ballasts, ensuring constant, reliable electrical performance. This means that over the system’s entire service life, there is always 100% electrical power available, for complete curing at high speeds.

REHABILITATION VEHICLE CONSTRUCTION

RELINE AMERICA offers the complete turnkey construction of rehabilitation vehicles, custom-built according to contractor requirements. These vehicles are equipped with our latest UV curing technology, and all equipment required for use on construction sites.

Fully automated and computerized controls are built into the installation equipment on our curing operations trucks, which help technicians follow the proper curing process protocols. RELINE offers users equipment precisely tailored to the Alphaliner, for trenchless pipeline renovation projects that are successful the first time

We offer the same features on our service vehicle builds, for use with the UV curing vehicle on the construction site.

AVAILABLE LIGHT SOURCES:

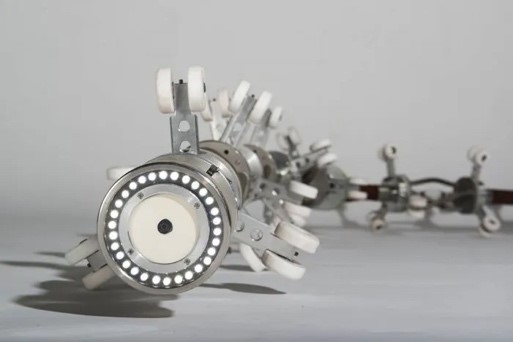

SPEEDCHAIN – 9 x 450w to 700w for DN 150 – DN 500 (DN 600 optional)

With the RA2000 UV curing system, the power consumption of the UV lamps of the RELINE AMERICA Speed Chain light train can be adjusted in stages, from 450 watts to 700 watts.

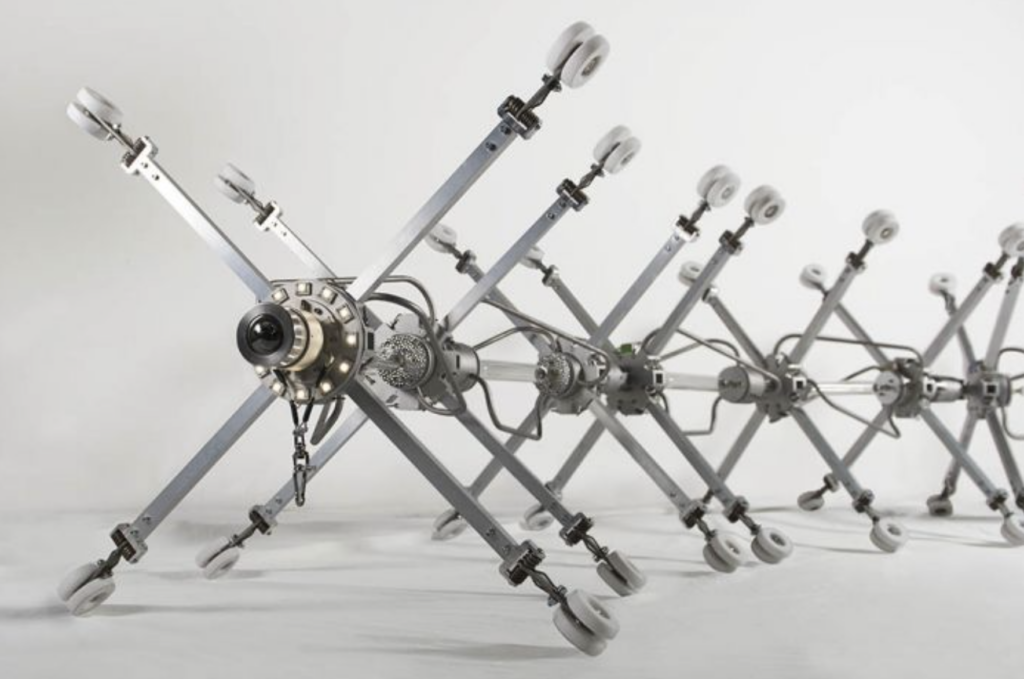

RapidChain – 8 x 1200w to 2000w for DN 600 – DN 1500 – Switchable with 1,200 W, 1,600 W, 2,000 W

The power usage of UV lamps of the RELINE AMERICA Rapid Chain light train can be adjusted with the RA2000 UV curing system with 1,200 W, 1,600 W, 2,000 W lamps.

RA2000 Professional

Our RA2000 curing systems are available as a both mobile model (RA2000 mobile) and as a permanent truck case installation (RA2000 professional). The mobile version offers maximum flexibility. Even hard-to-reach construction sites can be accessed with its smaller, more agile footprint. The UV-professional version enables the efficient renovation of very long sewer sections in one operation, thanks to the generous 1000 foot cable drum.

RA2000 Available Models:

AVAILABLE LIGHT SOURCES:

RA4000 MOBILE AND RA4000 PROFESSIONAL

Our RA4000 UV curing system is available as both a mobile version and as a permanent truck case installation. The RA4000 Mobile has a cable drum with cable lengths of up to 656 ft/200 meters, and an additional integrated control panel. The RA4000 Professional is equipped with an extra-long curing cable of 1148 ft/350 meters.

Features Include:

QUALITY TRACKER SYSTEM

Our innovative Quality Tracker System™, which allows installation crews to control how the ALPHALINER® cures, is game-changing technology that puts us a step ahead of the competition. This system allows installers to see how the liner is conforming to a pipe as it goes in, and to fix potential defects before the liner cures. During that curing process, automated computer controls in our installation equipment guide installers through each step, providing full protocols for critical factors such as light temperatures and how fast the light train travels. The end result: A system that minimizes risk and maximizes the chances for a properly cured liner. Here are some of its key components:

Built-in closed-circuit television (CCTV) camera provides installers with a live video feed inside the liner, prior to the start of curing.

Quality assurance is built into the framework of our installation equipment. These controls help facilitate smooth, successful installations and reduce the possibilities of human error.

The Quality Tracker System™ enables faster installations, because the levels of ultraviolet light are constantly monitored and adjusted. This ensures that the light train delivers the optimal amount of light intensity and wavelength, for just the right amount of time required for proper curing.

The ALPHALINER® system’s ultraviolet lightbulbs are central to the curing process. Our lights are tuned and optimized to the photo-initiator employed in our resin systems, and can be adjusted to various wattage levels. This enables installers to adjust to varying pipe diameters and geometries.

State-of-the-art touchscreen controls display all vital installation information, which is captured by QUALITY TRACKER SYSTEM™ software in real-time during the curing process. This information includes temperatures, monitored by infrared sensors and a thermocouple built into the light train; air pressure inside the pipe, which assures the liner remains fully expanded throughout the curing process; and the speed of and distance traveled by the light train.

If the installation crew encounters an issue on the project site, our 24/7 Support Team can remotely access the curing equipment to troubleshoot and assist for successful installation.

PLEASE CONTACT US FOR A FREE QUOTATION AND TELL US MORE ABOUT YOUR PROJECT

Can’t Decide Which UV System is Best For You?

Reline America, Inc.

Corporate Headquarters

116 Battleground Avenue, Saltville, VA 24370 USA

Toll Free: 866 998 0808 | Local: 276 496 4000

info@relineamerica.com

Copyright ©2024 Reline America Inc.